-

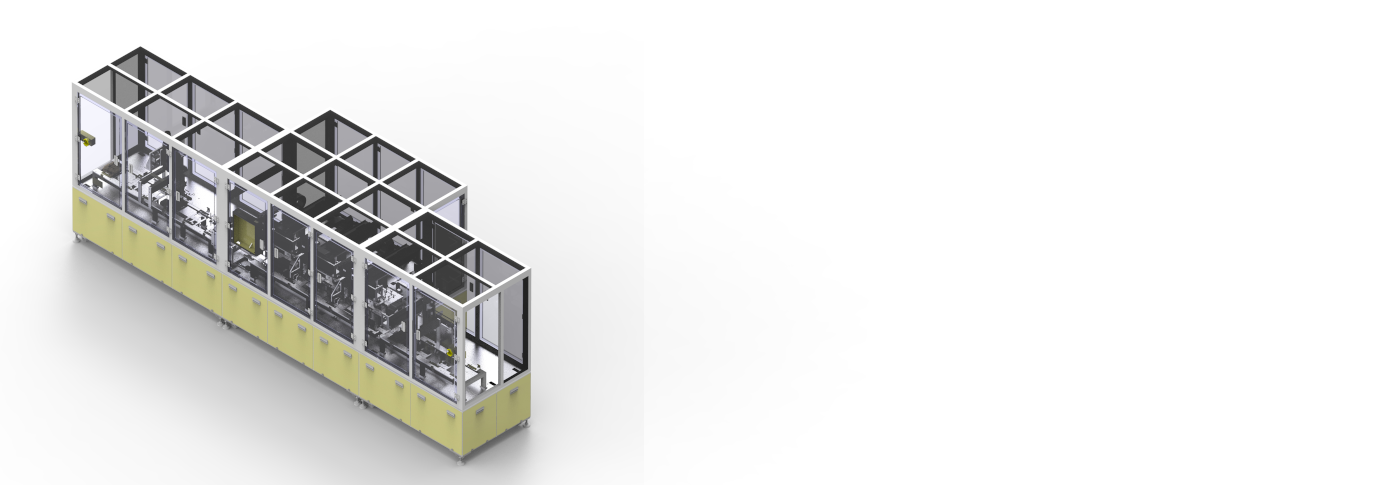

- Module Housing Assembling MC for Vehicle

- Module Housing assembly equipment for vehicles that automatically performs a series of processes including cooling fan motor assembly, automatic bolting, tape attachment, vision inspection, etc It is an automation equipment performed by the .

제품 특징- Production capacity (UPH): 180 ea/hr

- Four Auto Screw Bolt concurrent engagement capabilities

- Tape attachability in different sizes

- Vision Appearance Inspection Features

-

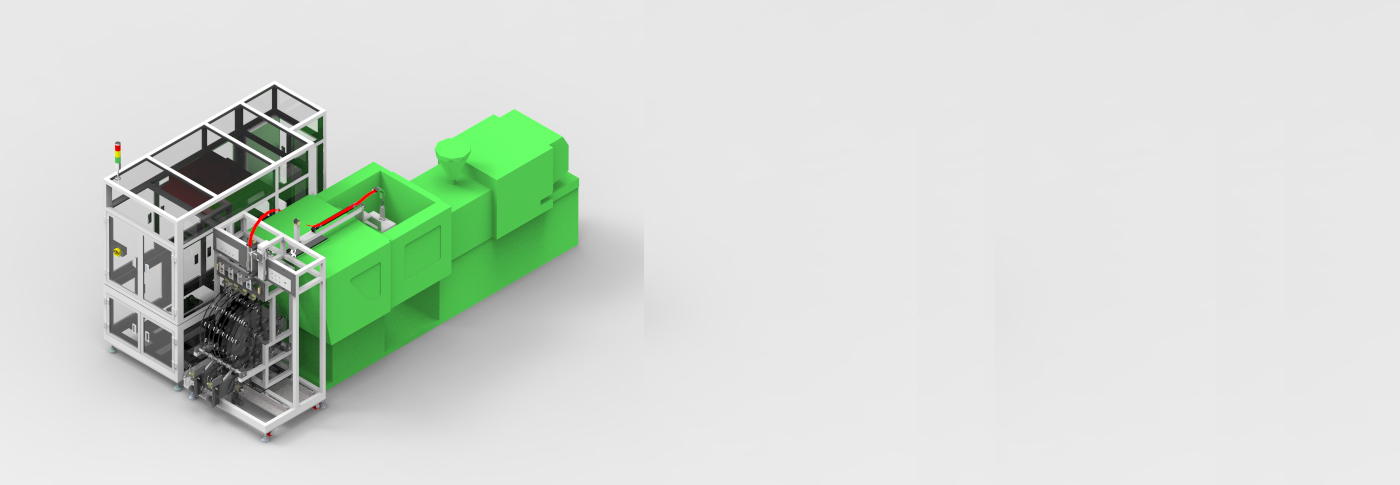

- VCM Auto Blow & Suction

- This equipment automatically loads VCM products stacked on a tray and performs blowing and suction cleaning in the cleaning chamber.

제품 특징- Production Capacity (UPH): Over 4,000 units

- Cleaning Time: 50 seconds per piece

- Air Blow Nozzles: Top and bottom

- Tray-based supply and discharge

- Auto Loading: Multi-stack tray supply

- Auto Unloading: Multi-stack tray discharge

-

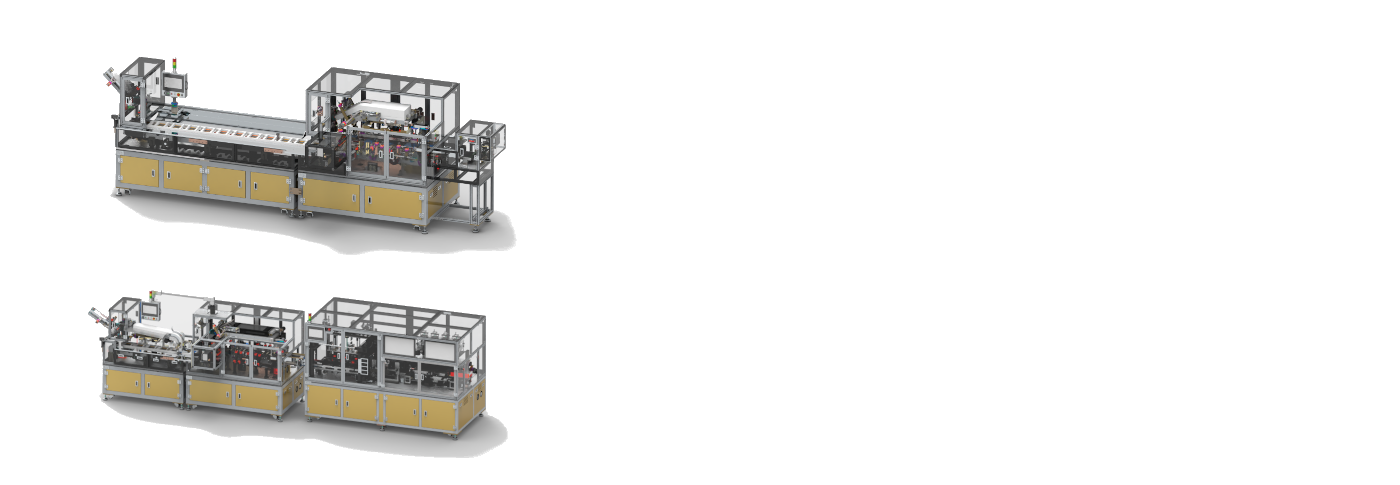

- VCM Lens Magazine Handler MC

- This equipment automatically supplies two VCM Lens Trays containing products to a process carrier and then automatically loads them into a magazine.

제품 특징- Production Capacity (UPH) : Over 514 units ( By Tray )

- Lens input 4 lane configuration

- When inserting a lens, two types of normal/inverted are available

- Lens Tray Multi-Stage Stacking Supply

- Lens Tray Detachment Inspection Function (Vision)

- Auto Loading (Tray multi-level stacking supply )

- Auto Unloading (Magazine load discharge )

-

- VCM Coil Auto Stripping MC

- Enamel cladding of lead wire of VCM Coil parts loaded on the tray It is a device that removes it with a laser

제품 특징- Production capacity (UPH): Over 560 units

- Laser stripping after checking the location of Wire with Vision

- After the upper surface laser stripping, in reverse, laser stripping

- Input/Output by Magazine

- Auto Loading (Magazine Load Supply)

- Auto Unloading (Magazine Load Emission)

-

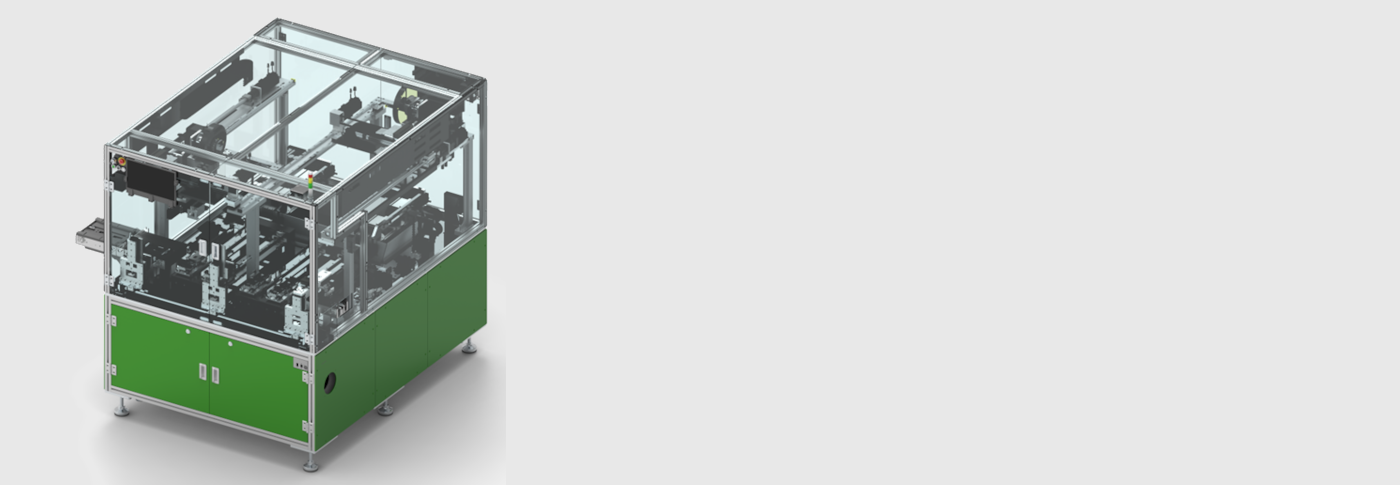

- Flex Array Pick & Place MC

- Auto the Flex Array product received on the Soft Tray as a process carrier Pick & Place equipment.

제품 특징- Separate and insert one multi-stage loaded product tray at a time

- Remove the Sus Cover for Flex Seating and Reunite After Flex Seating

- Apply Vision for Flex Product Settlement Status

- Load Pick & Place completed carrier magazine

-

- Injection Insert Automation Line

- The Reel-type injection insert is automatically connected and supplied to the injection mold, Laser marking on finished products and trimming as individual products Therefore, it is an in-line equipment that automatically loads on the shipment tray.

제품 특징- Insert material supply: Reel unit supply

- Supply up to 4 Reel and auto-connect Reel

- Reel unit injection completed product individual trimming

- Automatically load individual product shipping trades

- Product Tray Multistage Load and Automatic Emission Features

-

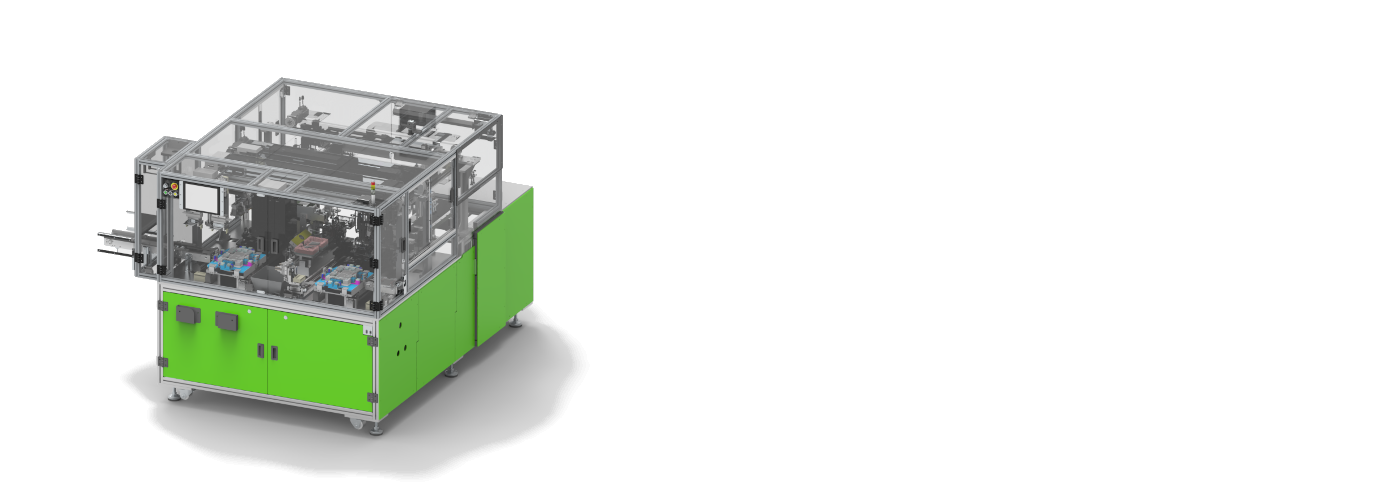

- Cartoner Machine

- Contact Lens, pharmaceuticals, cosmetics, medical supplies, etc Equipment to pack in an automatic Caton Box

제품 특징- Production capacity: UPH: 3000ea, 50 [pcs/min] or higher

- Industrial Standard PLC Control System

- Intermittent Drive (Step By Step)

- Carton Box Size Adjustment Easy to control production speed

- Compact structure, easy to operate

- Fabrication of Hotmelt, Tuck-in structures

- In-Line Production of Weight Sorter, Labeling Machine, and Laser Marker

- Auto Loading Response

- Auto Unloading Response

-

- Protective Vinyl Removal M/C

- It's attached to the finished product during the cell phone packaging process It is a facility that automatically removes protective vinyl for processing

제품 특징- Production capacity: 450 EA or higher (UPS/hour)

- Cell phone display face, back cover's vinyl peeling

- All varieties can be handled with ALIGN JIG (FOLD, FLIP, SMART PHONE)

- Discharge in the same direction after removing both sides with 180 degree reversal action

-

- Auto Assembler Back Cover Attach

- Equipment that attaches and presses back cover materials to input products

제품 특징- Production capacity (UPH): over 400 units

- Back Cover Material Trays can be stacked and fed

- Inspection of Tray materials with Vision

- Back Cover Pick Up & Protective Vinyl Peeling

- Press after attaching with Set

-

- SET LOADER V2

- Equipment placed at the end of the production line to load the assembled product into the loading box

제품 특징- Automatic supply of stacked boxes by AGV

- Move 1 box to use separately setting

- Multi-variety production with multi-joint robots

- When completed, Robot opens the label, puts it in the box, and discharges it to the side

- Automatically eject by calling AGV when loading 2 boxes

-

- high-speed bolting machine

- Equipment that automatically engages the BOLT that fixes the PCB inside various products such as SMART PHONE and TABLET

제품 특징- Manual input/discharge of workers

- Automatically input the fastening position after capturing VISION in the facility

- SCREW PICK-UP Method

- Fastening time: 1 Point / 2s

- Position accuracy: 0.05 mm